Product Center

Agriculture Equipment Air Filter Manufacturer – SK-1001AB Excavator air filter for KOMATSU 600-181-6540 600-181-6550 HITACHI 4129905 4129907 CATERPILLAR 0964175 4I7575 3I1426 CASE 161863A1 – Qiangsheng

Agriculture Equipment Air Filter Manufacturer – SK-1001AB Excavator air filter for KOMATSU 600-181-6540 600-181-6550 HITACHI 4129905 4129907 CATERPILLAR 0964175 4I7575 3I1426 CASE 161863A1 – Qiangsheng Detail:

The function of construction machinery air filters

The function of construction machinery air filters

The function of construction machinery air filters is to effectively filter impurities in oil, reduce oil flow resistance, ensure lubrication, and minimize the wear of components during operation

The function of the fuel filter element is to effectively filter impurities such as dust, iron dust, metal oxides, and sludge in the fuel oil, prevent the fuel system from clogging, improve the combustion efficiency, and ensure the stable operation of the engine; The filter element is located in the intake system of the engine, and its main function is to effectively filter the air entering the cylinder, thereby reducing the early wear of the cylinder, piston, piston ring, valve, and valve seat, preventing black smoke, and improving the normal operation of the engine. Power output is guaranteed.

The research results show that the wear problems of the engine mainly include three different forms: corrosive wear, contact wear and abrasive wear, and the abrasive wear accounts for 60%-70% of the wear value. The filter element of construction machinery usually works in a very harsh environment. If we do not form a good filter element for information protection, the cylinder and piston ring of the engine will develop and wear out quickly. The main function of “three cores” is to reduce the damage of abrasives to the engine by effectively improving the filtration of air, oil and fuel, and to ensure the efficiency of automobile engine operation management.

Typically, the engine oil filter is changed every 50 hours, then every 300 hours of work, and the fuel filter is changed every 100 hours, then 300 hours, depending on the quality between oil fill and fuel Due to the difference in level, the manufacturer recommends appropriately extending or shortening the replacement cycle of the air filter. The replacement cycle of the air filter used by different models varies with the air quality of the working environment. The replacement cycle of the air filter will be adjusted as appropriate. Replace internal and external filters.

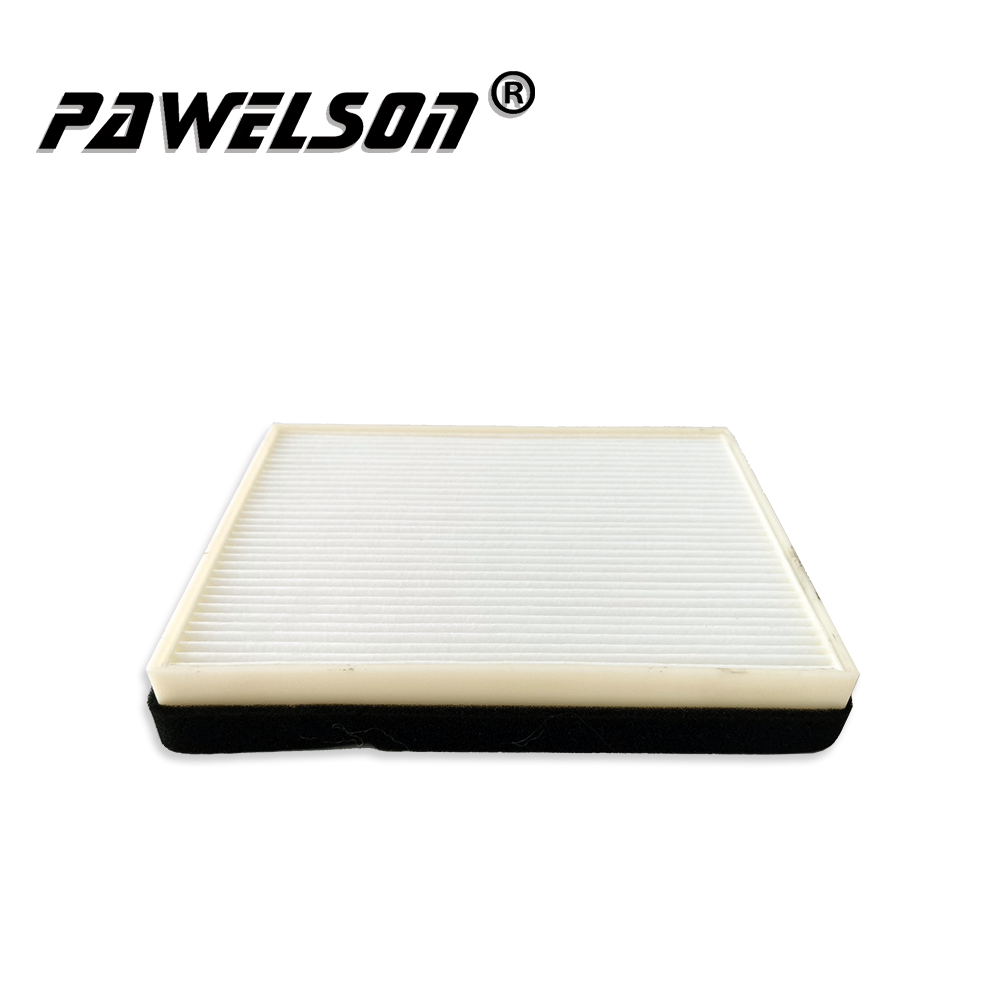

Product description

SK-1001AB Excavator air filter for KOMATSU 600-181-6540 600-181-6550 HITACHI 4129905 4129907 CATERPILLAR 0964175 4I7575 3I1426 CASE 161863A1

A:

| QS NO. | SK-1001A |

| OEM NO. | KOMATSU 600-181-6540 KOMATSU 600-181-6550 HITACHI 4129905 HITACHI 4129907 CATERPILLAR 0964175 CATERPILLAR 4I7575 CATERPILLAR 3I1426 CASE 161863A1 |

| CROSS REFERENCE | R800103 P800103 AF4567 C19457 P535365 P815050 P529587 A-5627 |

| APPLICATION | KOMATSU (PC120-6E、PC200-5、PC210-5、PC220-5) HITACHI EX200-1 CAT (E200B、E220B) KOBELCO (SK200、SK200-3) |

| OUTER DIAMETER | 187/235 (MM) |

| INNER DIAMETER | 120/17 (MM) |

| OVERALL HEIGHT | 376/388 (MM) |

B:

| QS NO. | SK-1001B |

| OEM NO. | KOMATSU 600-181-6560 HITACHI 4059818 CATERPILLAR 6I6582 LIEBHERR 6425724 LIEBHERR 7009286 VOLVO 7475191 |

| CROSS REFERENCE | P119374 AF490M P106834 C1281 A-6008 |

| APPLICATION | KOMATSU (PC120-6E、PC200-5、PC210-5、PC220-5) HITACHI EX200-1 CAT (E200B、E220B) KOBELCO (SK200、SK200-3) |

| OUTER DIAMETER | 117/145/139 (MM) |

| INNER DIAMETER | 87.5/17 (MM) |

| OVERALL HEIGHT | 334 (MM) |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Agriculture Equipment Air Filter Manufacturer – SK-1001AB Excavator air filter for KOMATSU 600-181-6540 600-181-6550 HITACHI 4129905 4129907 CATERPILLAR 0964175 4I7575 3I1426 CASE 161863A1 – Qiangsheng , The product will supply to all over the world, such as: Croatia, Porto, Angola, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.