Product Center

Buy Hepa Filter Supplier – K2841AB C271050 CF1810 China heavy truck air filter for GOLDEN DRAGON BUS 4592056695 211000005 211000004 4592056389 – Qiangsheng

Buy Hepa Filter Supplier – K2841AB C271050 CF1810 China heavy truck air filter for GOLDEN DRAGON BUS 4592056695 211000005 211000004 4592056389 – Qiangsheng Detail:

Problems to be paid attention to in the maintenance of diesel engine air filter

The starting devices of rural tractors and agricultural transport vehicles are equipped with air filters, oil filters and diesel filters, commonly known as “three filters”. The operation of “three filters” directly affects the operation function and service life of the starter. At present, quite a lot of drivers fail to maintain and protect the “three filters” according to the prescribed time and rules, resulting in frequent engine failures and premature entry into the maintenance period. Let’s take a look at it next.

The maintenance master reminds you: the protection and maintenance of the air filter, in addition to the regular and operation and maintenance requirements, should also pay attention to the following points:

1. The guide grille of the air filter should not be deformed or rusted, and its inclination angle should be 30-45 degrees. If the resistance is too small, it will increase and affect airflow. If the airflow is too large, the rotation of the airflow will be weakened and the separation from dust will be reduced. The outer surfaces of the blades do not need to be painted to prevent oxidation particles from entering the cylinder.

2. The ventilation mesh should be cleaned during maintenance. If the filter has a dust cup, the dust particle height should not exceed 1/3, otherwise it should be removed in time; the dust cup mouth should be tightly sealed, and the rubber seal should not be damaged or discard.

3. The height of the oil level of the filter should meet the standard requirements. If the oil level is too high, it will cause carbon deposits in the cylinder. Too low oil reduces the filter’s function and accelerates its wear.

4. When the metal mesh (wire) in the filter is replaced, the diameter of the hole or wire can only be slightly smaller, and the filling capacity cannot be increased. Otherwise, the functionality of the filter will be reduced.

Pay attention to the air leakage of the intake pipe, and the oil change and cleaning should be carried out in a place without wind and dust; the fan filter should be carried out in an environment with low humidity and high pressure air, and the blowing direction should be opposite to the air entering the filter screen; during installation, The folding directions of adjacent filters of Di should penetrate each other.

Product description

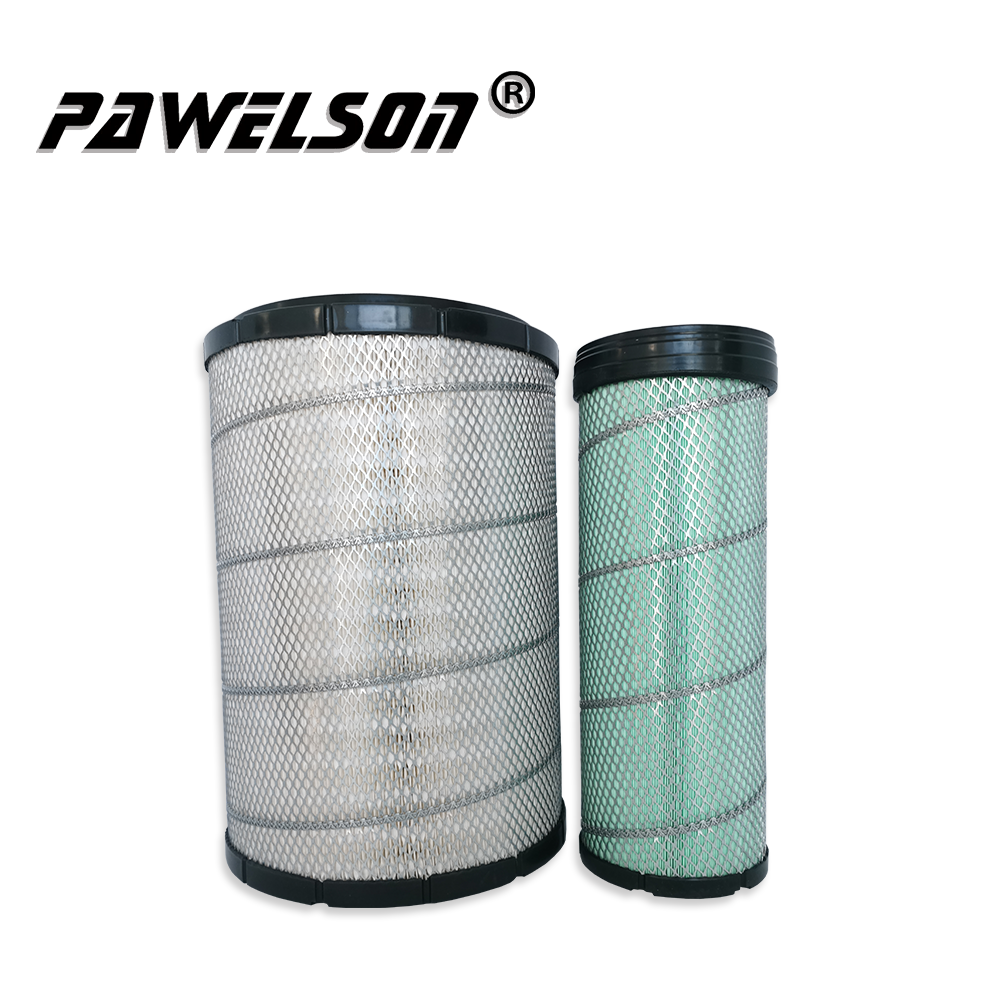

K2841AB C271050 CF1810 China heavy truck air filter for GOLDEN DRAGON BUS 4592056695 211000005 211000004 4592056389

A:

| QS NO. | K2841A C271050 |

| OEM NO. | GOLDEN DRAGON BUS 4592056695 GOLDEN DRAGON BUS 211000005 |

| CROSS REFERENCE | RS5538 A38050 AF26569 C271050 P953306 R003668 R004435 |

| APPLICATION | HEAVY DUTY TRUCK GOLDEN DRAGON BUS |

| OUTER DIAMETER | 279 (MM) |

| INNER DIAMETER | 201/185 (MM) |

| OVERALL HEIGHT | 414/453 (MM) |

B:

| QS NO. | K2841B CF1810 |

| OEM NO. | GOLDEN DRAGON BUS 211000004 GOLDEN DRAGON BUS 4592056389 |

| CROSS REFERENCE | RS5539 A38040 R004359 AF26570 CF1810 P641355 |

| APPLICATION | HEAVY DUTY TRUCK GOLDEN DRAGON BUS |

| OUTER DIAMETER | 182/178 (MM) |

| INNER DIAMETER | 167/162 (MM) |

| OVERALL HEIGHT | 427 (MM) |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

Product detail pictures:

Related Product Guide:

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for Buy Hepa Filter Supplier – K2841AB C271050 CF1810 China heavy truck air filter for GOLDEN DRAGON BUS 4592056695 211000005 211000004 4592056389 – Qiangsheng , The product will supply to all over the world, such as: Qatar, Norwegian, Malta, Our company always provides good quality and reasonable price for our customers. In our efforts, we already have many shops in Guangzhou and our products have won praise from customers worldwide. Our mission has always been simple: To delight our customers with best quality hair products and deliver on time. Welcome new and old customers to contact us for the future long term business relationships.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.