Product Center

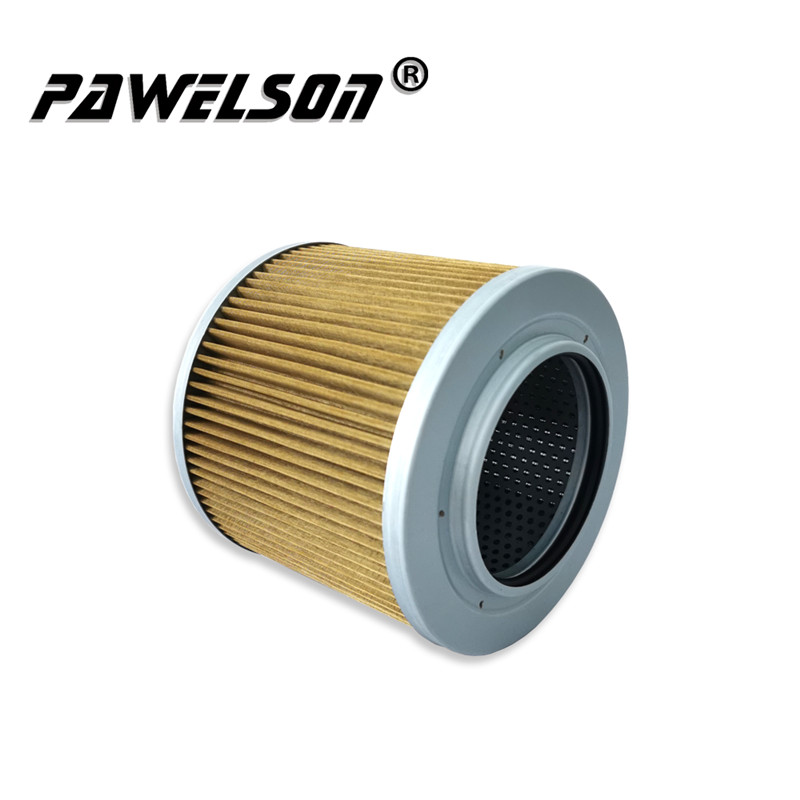

Buy Hydraulic Filter Element Factories – SY-2012 hydraulic oil filter Element for CASE excavator 4210224 – Qiangsheng

Buy Hydraulic Filter Element Factories – SY-2012 hydraulic oil filter Element for CASE excavator 4210224 – Qiangsheng Detail:

Hydraulic Filter Features:

1.We use imported depth type filter material,tapered pore structure,gradient filter,can intercept granule furthest, to extend theservice life.

2.We use high tech support materials.High tech support materials can not only play the role of support filter, material and avoiding compressive deformation,but also protect the materials from being damaged during processing.

3.We also use the special spiral wrapping belts,so thar filter layers can be connected firmly.Stationary pleated distance ensures the uniform flow when fluid penetrating the filter layer.Not only improving pressure drop,but also extending service life.

Function of hydraulic filters

There are many ways to collect contaminants in fluids. An appliance made of filter materials to capture contaminants is called a filter. Magnetic materials are used to adsorb magnetic contaminants called magnetic filters. In addition, there are electrostatic filters, separate filters, etc. In the hydraulic system, all the contaminant particles collected in the fluid are called hydraulic filters. The most widely used hydraulic filters are in addition to the use of porous materials or winding-type slits to intercept pollutants, as well as magnetic filters and electrostatic filters used in hydraulic systems.

After the above-mentioned impurities are mixed into the hydraulic oil, with the circulation of the hydraulic oil, they will cause damage everywhere, which will seriously affect the normal operation of the hydraulic system. Flow small holes and gaps are stuck or blocked; damage the oil film between the relative moving parts, scratch the surface of the gap, increase internal leakage, reduce efficiency, increase heat generation, aggravate the chemical action of the oil, and make the oil deteriorate. According to production statistics, more than 75% of the faults in the hydraulic system are caused by impurities mixed in the hydraulic oil. Therefore, maintaining the cleanliness of the oil and preventing the contamination of the oil are very important for the hydraulic system.

The general hydraulic filter is mainly composed of a filter element (or filter screen) and a shell (or skeleton). Numerous tiny gaps or pores on the filter element constitute the flow area of the oil. Therefore, when the size of the impurities mixed in the oil is larger than these tiny gaps or pores, they will be blocked and filtered out of the oil. Because different hydraulic systems have different requirements, it is impossible to completely filter the impurities mixed into the oil, and sometimes it is not necessary to be demanding.

Product description

| QS NO. | SY-2012 |

| CROSS REFERENCE | 4210224 |

| DONALDSON | P764679 |

| FLEETGUARD | HF28925 |

| ENGINE | EX200-1/2/5 JESSIEJS200/220/240/290 |

| VEHICLE | CASE220//210/240B |

| LARGEST OD | 150(MM) |

| OVERALL HEIGHT | 135(MM) |

| INTRNAL DIAMETER | 87 M10*1.5 |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Buy Hydraulic Filter Element Factories – SY-2012 hydraulic oil filter Element for CASE excavator 4210224 – Qiangsheng , The product will supply to all over the world, such as: USA, Washington, Latvia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we have been going to have a bright prospect and to be distributed all over the world in the years to come.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!