Product Center

Buy Hydraulic Filter Element Manufacturers – SY-2009 hydraulic oil filter factories for oem no. 205-60-51270 R36P0019 – Qiangsheng

Buy Hydraulic Filter Element Manufacturers – SY-2009 hydraulic oil filter factories for oem no. 205-60-51270 R36P0019 – Qiangsheng Detail:

Product Maintenance

Importance Of Hydraulic Filters Routine Maintenance:

Routine maintenance. It sounds boring and in fact, it isn’t exactly an earth-shattering event. Regardless of how much excitement it elicits, it is also a necessary evil when properly maintaining your hydraulic system.

With its main function to remove dirt and particles from the hydraulic components. Particle contamination can wreak havoc on your system, with the potential to cause malfunctioning parts, component failure, and downtime for your mobile equipment.

Preventative Maintenance Can Save You Time and Money

Rather than playing the game of too early or too late, implementing a maintenance schedule can help streamline your filter upkeep. With a maintenance schedule, you can monitor your filter capacity levels, knowing when they should be changed. This can allow for less downtime and gives you the ability to maintain an efficient, well-maintained hydraulic system.

Why Use Hydraulic Filters?

Hydraulic filters are mainly used in varieties of hydraulic system in the industry. These filters have many advantages that ensures safe working of hydraulic system. Some of those advantages of hydraulic oil filters are listed below.

Eliminate the presence of foreign particles in hydraulic fluid

Protect the hydraulic system from the dangers of particle contaminants

Improves the overall efficiency and productivity

Compatible with most of the hydraulic system

Low cost for maintenance

Improves the service life of hydraulic system

Product description

| QS NO. | SY-2009 |

| CROSS REFERENCE | 205-60-51270 R36P0019 |

| DONALDSON | P502215 |

| FLEETGUARD | HF7956 |

| ENGINE | PC200-1/2/5 PC300-1/2 PC400-1/2 PC200-3 PC-200-5 |

| VEHICLE | SK100/SK120/SK150/SK00/SK220/SK300 |

| LARGEST OD | 42(MM) |

| OVERALL HEIGHT | 85(MM) |

| INTRNAL DIAMETER | 23 |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

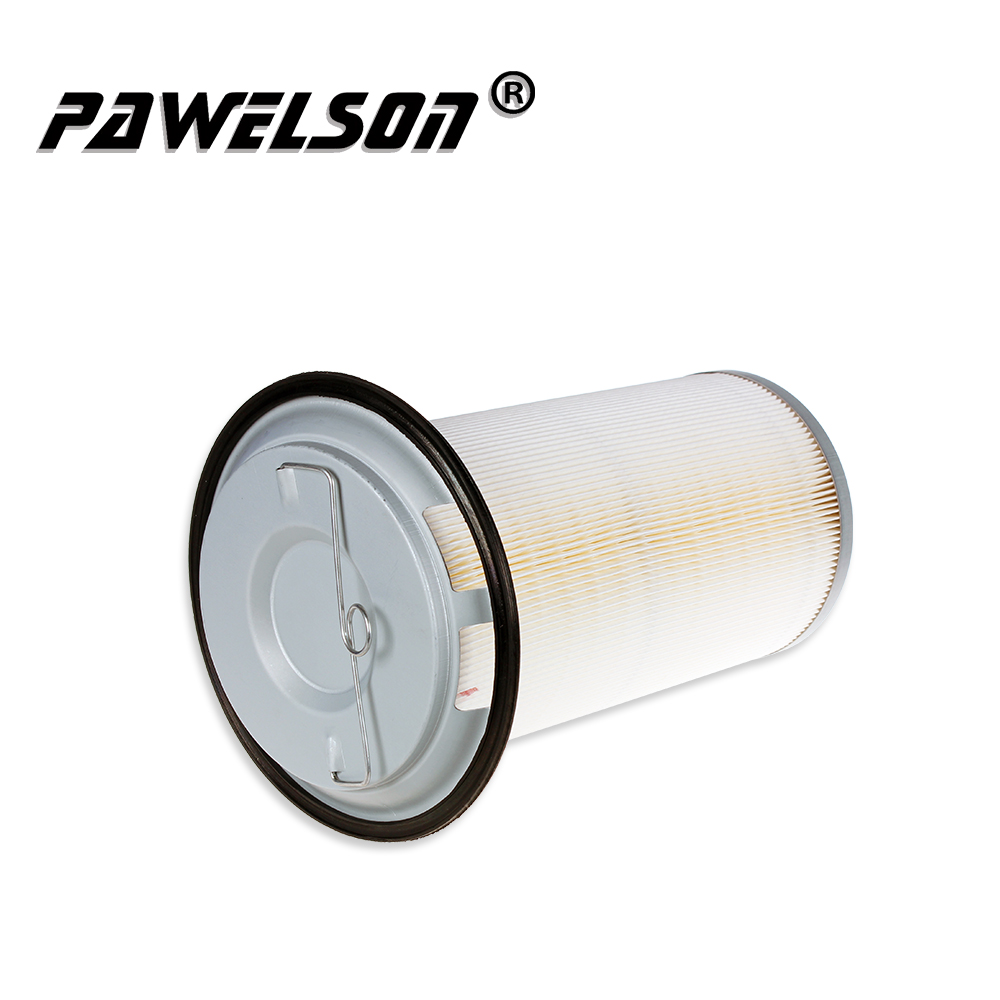

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Buy Hydraulic Filter Element Manufacturers – SY-2009 hydraulic oil filter factories for oem no. 205-60-51270 R36P0019 – Qiangsheng , The product will supply to all over the world, such as: Istanbul, kazakhstan, Rwanda, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!