Product Center

China Wholesale Truck Hydraulic Oil Filter Factory – SY-2004 hydraulic oil filter fits for 07063-01210, 205-60-51430 24749404A suppliers – Qiangsheng

China Wholesale Truck Hydraulic Oil Filter Factory – SY-2004 hydraulic oil filter fits for 07063-01210, 205-60-51430 24749404A suppliers – Qiangsheng Detail:

What Does A Hydraulic Filter Do?

Hydraulic fluid is the most important part of every hydraulic system. In hydraulics, no system works without a proper volume of hydraulic fluid. Also, any variation in fluid level, fluid properties, etc.. can damage the entire system we are using. If the hydraulic fluid has this much importance, then what will happen if it gets contaminated?

Hydraulic Filter Element Is Mainly Used For

1.Construction machinery (excavators, drilling RIGS, pile drivers, Forklifts, loaders, pavers, etc.)

2.Large CNC machine tool

3.Power plant (wind, hydraulic, thermal) fuel resistance, jacking pump, coupler, gear box, coal mill, flush, oil filter, etc., steel mill, hydraulic pump station, lubricating system, port machinery, etc

4.Printing machine, warp knitting machine

How to clean Hydraulic filter?

Many people think that hydraulic oil filter elements are difficult to clean without cleaning, which will greatly reduce the service life of hydraulic oil filter elements. In fact, there are ways to clean the hydraulic oil filter element. Generally, the original hydraulic oil filter element is made of stainless steel wire mesh. To clean such a hydraulic oil filter element, you need to soak the filter element in kerosene for a period of time. It can be easily removed by blowing it out with wind. It’s stained. However, it should be noted that this method cannot be used if it is not for the original hydraulic oil filter element that is too dirty, and it is better to replace it with a new hydraulic oil filter element.

Product description

| QS NO. | SY-2004 |

| CROSS REFERENCE | 07063-01210, 205-60-51430 24749404A |

| DONALDSON | P551210 |

| FLEETGUARD | HF6319 HF7953 |

| ENGINE | SK200-2-3/SK210/SK250LC, CASECX240/210/360/300, PC360-3/PC300-3/PC400-3 PC210-6/PC230-6/PC250-6/PC750-6/ |

| VEHICLE | DH220-5/DH220-7/DH450 |

| LARGEST OD | 150(MM) |

| OVERALL HEIGHT | 454/450(MM) |

| INTRNAL DIAMETER | 110 |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

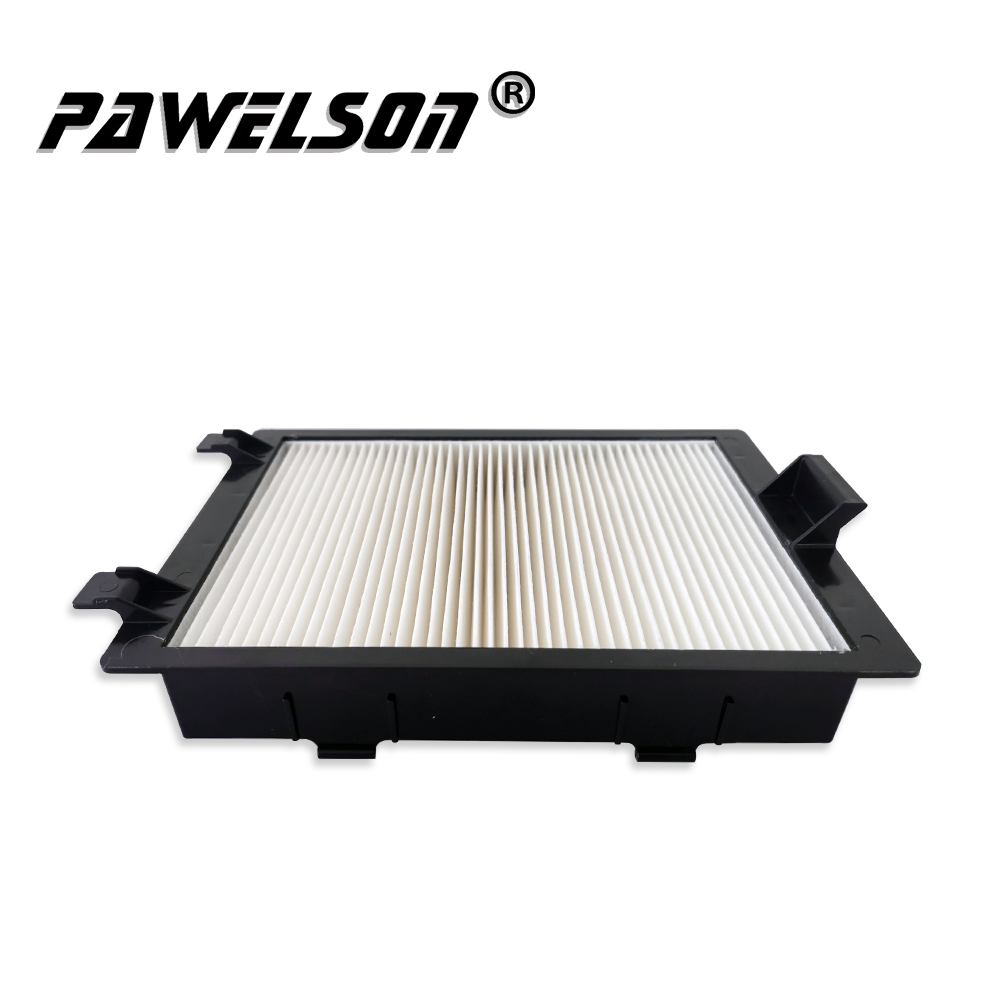

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for China Wholesale Truck Hydraulic Oil Filter Factory – SY-2004 hydraulic oil filter fits for 07063-01210, 205-60-51430 24749404A suppliers – Qiangsheng , The product will supply to all over the world, such as: Australia, United Kingdom, Bangkok, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.