Product Center

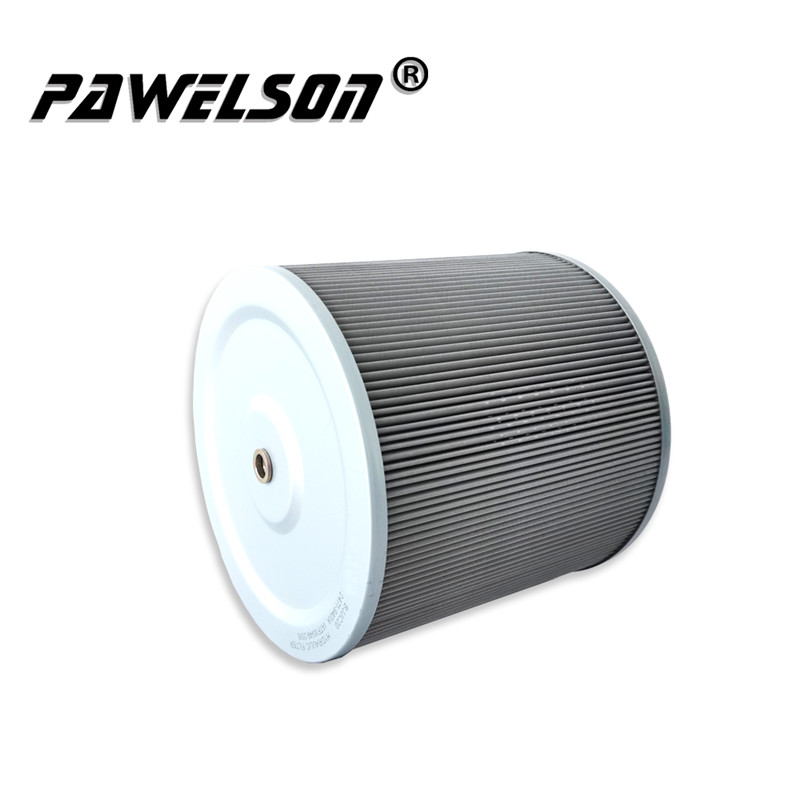

Excavator Hydraulic Oil Filter Suppliers – SY-2021 high quality hydraulic filter for 2471-9401A 4237660 – Qiangsheng

Excavator Hydraulic Oil Filter Suppliers – SY-2021 high quality hydraulic filter for 2471-9401A 4237660 – Qiangsheng Detail:

Hydraulic Filter Element Is Mainly Used For

1.Construction machinery (excavators, drilling RIGS, pile drivers, Forklifts, loaders, pavers, etc.)

2.Large CNC machine tool

3.Power plant (wind, hydraulic, thermal) fuel resistance, jacking pump, coupler, gear box, coal mill, flush, oil filter, etc., steel mill, hydraulic pump station, lubricating system, port machinery, etc

4.Printing machine, warp knitting machine

Importance Of Hydraulic Filters Routine Maintenance

Routine maintenance. It sounds boring and in fact, it isn’t exactly an earth-shattering event. Regardless of how much excitement it elicits, it is also a necessary evil when properly maintaining your hydraulic system.

With its main function to remove dirt and particles from the hydraulic components. Particle contamination can wreak havoc on your system, with the potential to cause malfunctioning parts, component failure, and downtime for your mobile equipment.

Preventative Maintenance Can Save You Time and Money

Rather than playing the game of too early or too late, implementing a maintenance schedule can help streamline your filter upkeep. With a maintenance schedule, you can monitor your filter capacity levels, knowing when they should be changed. This can allow for less downtime and gives you the ability to maintain an efficient, well-maintained hydraulic system.

How to clean Hydraulic filter?

Many people think that hydraulic oil filter elements are difficult to clean without cleaning, which will greatly reduce the service life of hydraulic oil filter elements. In fact, there are ways to clean the hydraulic oil filter element. Generally, the original hydraulic oil filter element is made of stainless steel wire mesh. To clean such a hydraulic oil filter element, you need to soak the filter element in kerosene for a period of time. It can be easily removed by blowing it out with wind. It’s stained. However, it should be noted that this method cannot be used if it is not for the original hydraulic oil filter element that is too dirty, and it is better to replace it with a new hydraulic oil filter element.

Product description

| QS NO. | SY-2021 |

| CROSS REFERENCE | 2471-9401A 4237660 |

| ENGINE | DH209/DH300-7/DH320 |

| LARGEST OD | 200(MM) |

| OVERALL HEIGHT | 208(MM) |

| INTRNAL DIAMETER | 113/ M10*1.5INWARD |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

Product detail pictures:

Related Product Guide:

All we do is always associated with our tenet " Customer first, Trust first, devoting on the food packaging and environmental protection for Excavator Hydraulic Oil Filter Suppliers – SY-2021 high quality hydraulic filter for 2471-9401A 4237660 – Qiangsheng , The product will supply to all over the world, such as: Hungary, Toronto, Albania, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!